Morenos - Packaging Machinery

- Food processing machinery

- Packaging machinery

- Filling-bottling equipment

- Product inspection equipment

- Packaging materials

- Robotic systems

Competition is becoming tougher! But with innovative and prominent packaging you can stand out from the crowd. Flexible packaging lines enable you to design portion sizes and package contents. The company provides you with a variety of tools to suit your particular markets.

At this website, you will find the best solutions for your success. The company is one of the most experienced and fastest growing sales agencies of industrial machinery for food processing equipment and packaging machinery.

What originally began in 1967 in Thessaloniki, Greece has grown and expanded into a network of four offices. With headquarters in Greece and branches in Serbia, Romania, and Bulgaria, the company circles the Balkan peninsula with a know-how that assures quality, efficiency, and rapid return on investment.

Local experienced staff serves the industries with the same principles that rule the organization in the last four decades.

Today, the company continues to provide best-in-class solutions based on a culture of innovation and problem-solving. Its core skills in various food technology techniques support the customers by speeding up innovation processes for their production needs.

Find more about our key products below:

As the world is changing and new challenges appear, the company launches innovative products and services to its customers.

Its vision is to become one of the customers’ best and most dedicated partners in the packaging industry by providing reliable solutions that contribute to customers’ constant growth.

We wish to thank all our customers for their confidence and support throughout these years. This is what made this website possible.

Selective reference to:

GREECE

REPUBLIC OF SERBIA

ROMANIA

BULGARIA

OTHER COUNTRIES

Know-how

The company employees a team of well – experienced consultants with a well-grounded, multiyear background in the packaging sector.

We always strive to equip our employees with the tools so as to develop their expertise and lead by market knowledge.

Turn-key plants

The company offers planning, development, supply and managing of the project.

Technical assistance

The company provides technical support throughout the installation of the plant or individual machines, so as to achieve customer service excellence.

Packaging materials

The company provides packaging systems with special packaging materials designed to achieve maximum capacity.

Our focus on innovative and sustainable packaging solutions enhances your product attractiveness, while reduces your environmental footprint.

Overhaul

In case you require a solution for your existing machine, we are in position to provide you with a value – adding solution by revamping your machine or providing technical advice for increasing your operational efficiency.

After-sales-support

Our company employees several service – engineers that locally offer technical assistance and spare parts to all clients, so as to reassure the seamless operation of your machine.

“Leonardo” Roller Miller is the most innovative and energy saver miller in the milling industry! Omas Industries ensure your investment continues delivering the utmost benefits and drive superior performance.

Benefits:

– Energy saving up to 70%

– Noiseless and maintenance free function

– Eliminate a whole floor in a new milling plant

(OKS-patented technology)

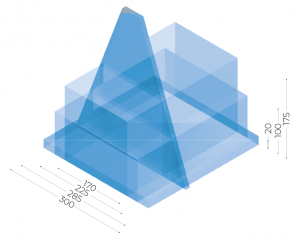

Rovema SBS brick pack machine is a versatile machine which packs an almost unlimited range of different products into bags.

– Higher productivity and efficiency of your production line

– Hermetically sealed product

– Compact and stackable dust tight pack

– More than 40 different bag top shapes

Products: powder, flour, pasta, rice, beans, etc.

![]() Optimal packaging with Rovema SBS 250

Optimal packaging with Rovema SBS 250

In-line machines measuring the liquid by means of inductive or mass-flowmeters with a recipe based control system for accurate and repeatable filling of both large and small volumes. Depending on the product to be filled, the machines can be supplied with a gravity or pressurized tank and volumetric or centrifugal pump with PID control. The filling machines are available also as filler-capper monoblocks.

The cappers are designed to treat all types of closures: pressure, aluminium screw, pre-threaded, oriented, dispensers and triggers for low, medium and high production. The machines, of sturdy construction, are suitable for use in various sectors of packaging, respecting easy cleaning, ease of use, strength and flexibility.

Robotic systems enhance your production lines and pave the way for faster, more efficient and better performance.

Automating your lines will help you:

☑ avoid repetitive tasks

☑ increase the operational performance

☑ have a fast return on your investment

Universal Robots provide the key to avoid repetitive tasks, while you re-deploy easily the robotic arms for various applications. Universal Robotic arms are the most valuable co-worker in your production line.

![]() New product launch: UR16e is here

New product launch: UR16e is here

Various labelling machine types create a unique, quality appearance for your product no matter whether it is small or big, round or angular. The labelling machines are characterized by low unit costs, low or no downtimes as well as easy set-up and a high level of accessibility. Our labelling machines can use wet glue, self-adhesive or hot-melt technology.

The linear labellers can guarantee:

☑ a high level of efficiency at top speeds of up to 60.000 bph

☑ low set-up times

☑ non-stop operation

The innovative rotary labellers fulfil customers’ individual requirements. Every label and every container can be processed using the appropriate labelling method. The different labelling technologies hotmelt, wet glue and self-adhesive can be combined as requested.

DENSO industrial robot arms offer reduced shaft whip and settling time, along with a lighter-weight arm and an optimized arm structure.

An extremely compact, space-saving design can be easily integrated into various applications. Electrical wiring and air piping are internally embedded in the robot arm, preventing interference with peripherals.

Benefits:

☑ high-speed, high-precision pick and place in assembly processes

☑ high repeatability without interruption

☑ high efficiency in packaging processes in the food, medical device, pharmaceutical and cosmetics sectors

FANUC provide a variety of payload robots according to your application-specific needs. FANUC industrial robots are easily customizable and dedicated to high throughputs. From light to heavy material handling there is an effective and affordable option for production enhancement.

Rovema vertical bagging machine is a versatile machine which packs an almost unlimited range of different products into bags. Delivering high performance and reliability renders Rovema a key player in the packaging industry.

Forming, filling and sealing in a single work process, fast and efficiently.

The optimum packaging raises the attractiveness of your product with different packages (pillow bag, stabilo, pillow bag with eurohole etc).

Products: rice, beans, candies, frozen foods, pasta, coffee etc.

![]() Perfect bag quality with Rovema BVC 260

Perfect bag quality with Rovema BVC 260

The TSW Industries have developed ideal solutions to handle the delicate soft cake, wire-cut and rotary moulded biscuits. Their technology ensures the smooth handling of the product even if there are variations in size and shape.

Accurate controls placement of filling and top cookie within+ or – 1 mm. with controls filling target weights to within ±1 %, saving cost on ingredient usage.

The development of depositing methods lead to indulgent eating textures and cost savings on raw ingredients.

Lineapack is one of the most innovative companies in the packaging sector, based in Italy.

Key benefits with Lineapack:

☑ High impact packaging materials

☑ Optimal protection and preservation of the product

☑ Eco-sustainable solutions

☑ High product quality

Check out more about Packaging materials for energy bars!

Lineapack is one of the most innovative companies in the packaging sector, based in Italy.

Key benefits with Lineapack:

☑ High impact packaging materials

☑ Optimal protection and preservation of the product

☑ Eco-sustainable solutions

☑ High product quality

Check out more about Packaging materials for dried fruits and nuts!

Lineapack is one of the most innovative companies in the packaging sector, based in Italy.

Key benefits with Lineapack:

☑ High impact packaging materials

☑ Optimal protection and preservation of the product

☑ Eco-sustainable solutions

☑ High product quality

Check out more about Packaging materials for the bakery!

X-ray systems for quality control of products deliver outstanding contamination detection of dense contaminants such as glass, metal, mineral stone, calcified bone, and high-density plastics in various packagings, i.e. trays, doypacks, cardboard, flowpacks, sachets and more.

The contaminant can be detected irrespective of its size, shape or location within the product itself. Products packaged with foil or metallized film do not constrain the effectiveness of x-ray detection.

Unlike traditional inspection systems, X-ray technology is not affected by changes in product temperature or moisture. The above ensures the minimization of false rejects.

AICON SCAN XR series detectors provide effective protection against contamination and various quality defects throughout all stages of production.

![]()

YAMATO checkweighers offer the utmost weighing accuracy at your production lines. Therefore, checkweighers permit high throughputs leading to increased line efficiency. The rejection of underweight and overweight products is translated to cost reduction, brand protection and ensures the consistency of your products.

Key benefits with YAMATO checkweighers:

☑ High precision at top speed increase line efficiency

☑ Reduction of product giveaway

☑ Low total cost of ownership

☑ Tool-free maintenance

![]()

![]() Yamato Checkweigher J-Series Brochure

Yamato Checkweigher J-Series Brochure

Yamato Multihead weighers combine high-speed operation with unparalleled accuracy and reliability. Their role is critical in order to improve the efficiency and the consistency of the production line.

Products: nuts, candies, cereals, salads, frozen food, pasta, bakery etc.

Check out more:

– Accurate weighing of cereal and granola for cereal bars

– Accurate weighing of confectionary

Mespack horizontal machines are the ideal solution for flexible packaging of liquid, solid and granule products.

Bag styles: doypak bags, pouches with zipper, pouches with valve, flat four-side-sealed pouches.

Products: cosmetics, cereals, juices, sauces, granule or liquid detergents, soups, syrups etc.

TSW Industries is a key player in flow wrapping solutions satisfying the most demanding of packaging needs. Their design ensures reliability in operation and high production rates.

There are solutions for mid to very high-speed wrapping requirements, or even a ‘stand-alone’ machine for a low-speed hand-fed application up to a fully automatic system.

Any add-ons can be easily integrated, ensuring the smooth operation of your packing line.

We participate in:

12/10/2019 – 14/10/2019

Metropolitan Expo, Athens, Greece

(Hall 3, Stand B16)

Online Invitation

30/10/2019 – 03/11/2019

Bucharest, Romania

(Hall A, Stand 48a)

Visit Website

16/05/2018 – 19/05/2018

Bucharest, Romania

(Hall B2, Stand 15a)

Visit Website

12/10/2018 – 15/10/2018

Metropolitan Expo, Athens, Greece

(Hall 3, Stand A5)

Visit Website

13/05/2018 – 19/05/2018

Novi Sad, Serbia

(Hall 2, Stand A4)

08/11/2018 – 11/11/2018

Inter Expo Center, Sofia, Bulgaria

(Hall 2, Stand A5)

Robotic systems can be an efficient and cost-effective solution!

Our new endeavour is TETTIX. We can provide you with the complete package and find solutions to your needs by industrial automation. We analyze your robotic system needs, provide a plan for automation, and put the automation into production.

TETTIX designs and manufactures industrial automation systems, acting mainly as a robot integrator. Consequently, the tailor-made industrial automation systems enable us to provide you with flexible and cost-saving solutions.

Robotic arms smartly and gently pick packaged and non-packaged items. The loading of the products into containers, trays, or even directly to flow-pack wrappers or tray loaders is easily programmable. The additional equipment such as vision systems and grippers enable each project to be easily customizable.

TETTIX has also been challenged to create a robotic case packing system that fits into the limited floor-space and accommodate frequent changeovers.

The innovative technological solutions, the reliability and the simplicity of use and safety, are characteristics that make our company a reliable partner for every kind of automation.